Industry

Excavation Industry

Usage

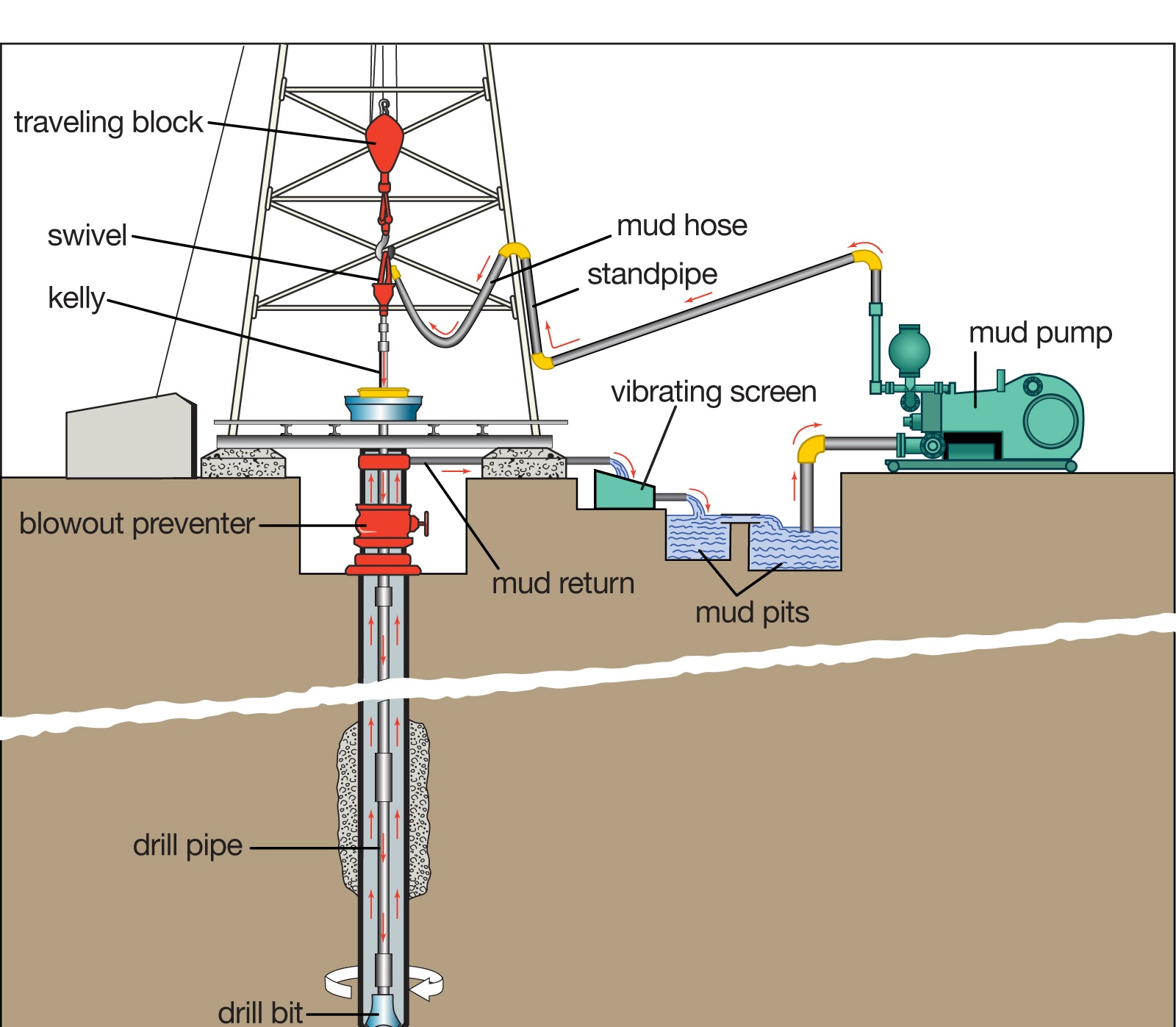

As a lubricant for drill bits and to cool them.

Delivery & Storage

- Valve type bags / PP or HDPE bags / Paper or customized palletizing facility available as per customer requirement like wrapped in Corrugated boxes, jumbo bags, & wooden boxes with SPECIAL packing material support so that bags will not be damaged during the transit

- Big-bags Store in dry/aerated space: with laminated or with liners with customized palletizing

Recommendations:

- Walls for Diaphragm and Cut-Off

- Jacking Pipe

- Muds Drilling

- Bore, Grouting, and Piling

- Under high pressure and high-temperature drilling conditions, it can be used.

- Mix with water of decent quality

- Using high-shear blenders

- Often use Norm in drilling work

- Ceramics, additives. So the use of Regular Bentonite is prudent.